In modern construction, the ability to span long distances without the need for multiple supports is crucial for creating open spaces in bridges, buildings, and industrial structures. One of the key structural elements used to achieve this is the plate girder. Plate girders are fabricated beams made from steel plates welded or bolted together, often forming an “I” or “box” section. They are highly versatile and can be customized to carry heavy loads over significant distances. But a common question arises: what is the maximum span for a plate girder?

Understanding Plate Girders

A plate girder is essentially a large, built-up beam designed to carry heavy loads over long spans. Unlike rolled steel sections that come in standard sizes, plate girders are fabricated to meet specific project requirements. Typically, they consist of:

-

Web plate – the vertical section that resists shear forces.

-

Flange plates – the horizontal sections at the top and bottom that resist bending.

-

Stiffeners – additional plates welded to the web to prevent buckling under heavy loads.

Because they can be fabricated in different dimensions, plate girders are used in bridges, industrial buildings, and warehouses where long, unobstructed spans are necessary.

Typical Span Range of Plate Girders

In general, plate girders are economical and practical for spans ranging from 10 meters (33 feet) to about 100 meters (328 feet). This makes them suitable for medium- to long-span applications, especially where rolled steel beams would be insufficient.

-

For short spans under 10 meters, rolled sections are usually more cost-effective.

-

For medium spans between 10 and 40 meters, plate girders are common in building construction.

-

For long spans of 40 to 100 meters, plate girders are widely used in bridges and industrial applications.

Beyond 100 meters, more specialized structural systems, such as cable-stayed bridges, trusses, or box girders, often become more economical and efficient.

Factors That Influence Maximum Span

The maximum span a plate girder can cover depends on several engineering factors:

-

Load Requirements

The type of load (dead load, live load, or dynamic load) directly impacts the design. Heavier loads require deeper girders and stronger flanges, which may limit the feasible span. -

Depth of the Girder

A deeper girder can span a longer distance. As a rule of thumb, the depth of a plate girder is often 1/12 to 1/20 of the span length. For example, a 30-meter span might require a girder depth of 1.5 to 2.5 meters. -

Type of Construction

-

Simply supported girders have shorter economical spans.

-

Continuous girders (spanning over multiple supports) can cover longer spans efficiently.

-

-

Material Properties

High-strength steel allows for thinner, lighter girders that can span greater distances compared to conventional steel grades. -

Stiffeners and Bracing

The use of stiffeners reduces the risk of web buckling, allowing girders to carry more load over longer spans safely.

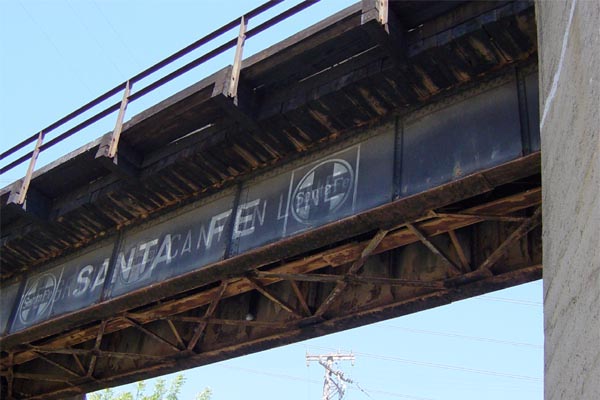

Examples of Plate Girder Spans in Practice

-

Highway Bridges: Plate girders are widely used in highway overpasses with spans between 20 and 50 meters.

-

Railway Bridges: Heavier loads require deeper girders, often spanning 30 to 80 meters.

-

Industrial Buildings: Plate girders can span wide factory floors or warehouses up to 40 meters, reducing the need for interior columns.

In some specialized cases, with advanced design techniques and materials, plate girders have been used for spans approaching 120 meters, but this is at the upper limit of practicality.

Conclusion

So, what is the maximum span for a plate girder? In most cases, plate girders are effective for spans ranging from 10 to 100 meters. The exact maximum depends on load conditions, girder depth, material strength, and structural design. While they are not typically used for ultra-long spans beyond 100 meters, plate girders remain a cost-effective and reliable solution for medium to long-span structures such as bridges, industrial buildings, and warehouses.

Their adaptability in design and fabrication makes them a cornerstone of modern structural engineering, offering strength and efficiency where rolled sections and other beams fall short.

Post time: Sep-12-2025