When discussing metal roofing, siding, or construction materials, the terms galvanized and corrugated are often used interchangeably. However, they refer to very different characteristics of metal products. Understanding the difference between galvanized and corrugated is essential for selecting the right material for construction, industrial, or agricultural applications.

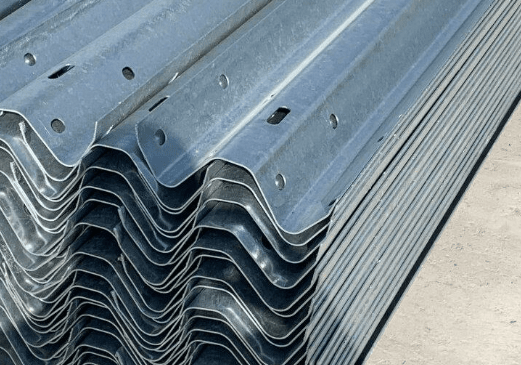

What Does Galvanized Mean?

Galvanized refers to a protective treatment applied to steel or iron. Galvanization involves coating the metal with a layer of zinc, most commonly through a process called hot-dip galvanizing. This zinc layer protects the underlying metal from corrosion by acting as a barrier and by providing sacrificial protection if the surface is scratched.

Galvanized steel is widely used in environments where moisture, humidity, or outdoor exposure could cause rust. The zinc coating significantly extends the lifespan of the metal, making it suitable for roofing panels, fencing, structural components, and fasteners.

Key characteristics of galvanized metal include:

-

Excellent corrosion resistance

-

Long service life in outdoor conditions

-

Low maintenance requirements

-

Matte or spangled surface appearance

Importantly, galvanization affects the chemical and protective properties of the metal, not its shape or profile.

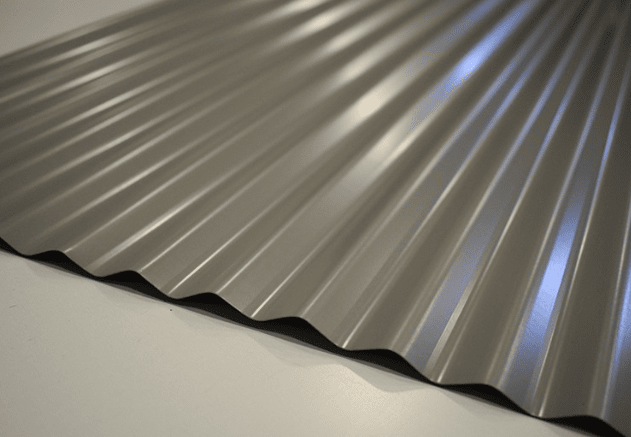

What Does Corrugated Mean?

Corrugated refers to the shape or profile of a metal sheet, not its coating. Corrugated metal has a series of parallel ridges and grooves formed through rolling or pressing. This wavy or ribbed design increases the strength and stiffness of the sheet without significantly increasing its weight.

Corrugation allows thinner metal sheets to span longer distances and withstand loads such as wind, rain, or snow. Corrugated metal is commonly used for roofing, wall panels, sheds, barns, and industrial buildings.

Key characteristics of corrugated metal include:

-

Increased structural strength and rigidity

-

Lightweight yet load-resistant design

-

Efficient water runoff due to ridged profile

-

Distinctive industrial or agricultural appearance

Corrugated sheets can be made from various materials, including steel, aluminum, and even plastic.

Galvanized vs Corrugated: Key Differences

The main difference between galvanized and corrugated lies in what each term describes:

-

Galvanized describes a surface treatment that protects metal from corrosion.

-

Corrugated describes a physical shape or profile that increases strength.

Because they describe different properties, galvanized and corrugated are not mutually exclusive. A metal sheet can be galvanized, corrugated, both, or neither.

Can Metal Be Both Galvanized and Corrugated?

Yes. In fact, many roofing and siding panels are galvanized corrugated steel. In this case, the steel is first coated with zinc for corrosion resistance and then formed into a corrugated profile for added strength. This combination is extremely popular in construction because it offers durability, structural efficiency, and cost-effectiveness.

Choosing Between Galvanized and Corrugated Materials

Since galvanized and corrugated refer to different aspects, the choice depends on your needs:

-

If corrosion resistance is your main concern, galvanized metal is essential.

-

If structural strength and rigidity are required, corrugated profiles are beneficial.

-

For outdoor roofing and siding, galvanized corrugated steel is often the best solution.

Consider factors such as climate, load requirements, budget, and aesthetics when selecting materials.

Common Applications

-

Galvanized metal: Fencing, structural framing, fasteners, outdoor equipment

-

Corrugated metal: Roofing sheets, wall cladding, agricultural buildings

-

Galvanized corrugated metal: Sheds, warehouses, barns, industrial roofs

Conclusion

The difference between galvanized and corrugated lies in function, not quality. Galvanized refers to corrosion protection, while corrugated refers to shape and structural design. Understanding this distinction helps you make informed decisions when selecting metal materials for construction or industrial use. In many cases, combining both features provides the best performance, durability, and value.

Post time: Jan-09-2026