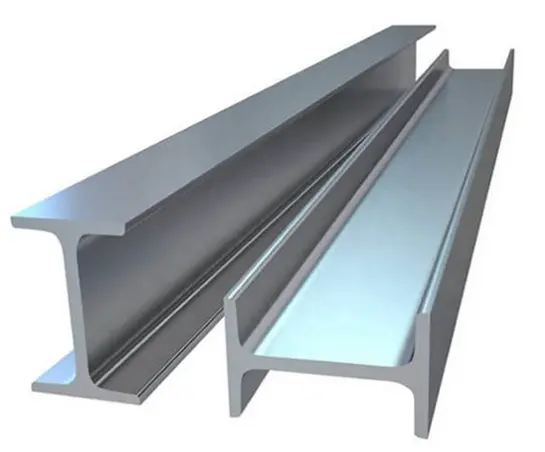

In the world of construction and structural engineering, few components are as foundational as the Universal Column (UC). Often referred to as an “H-beam” due to its distinctive cross-sectional shape, the universal column is the vertical backbone of modern architecture, from residential extensions to soaring skyscrapers.

If you are wondering, “what is a universal column?” or how it differs from a standard beam, this guide covers everything you need to know about its design, applications, and advantages.

Defining the Universal Column

A Universal Column is a hot-rolled structural steel section designed primarily to support vertical (axial) loads. While it looks similar to a Universal Beam (UB), its geometry is specifically engineered for compression rather than bending.

The defining characteristic of a UC is its “squarer” profile. Unlike beams, which are much taller than they are wide, the depth and width of a universal column are typically very similar. This symmetrical design provides excellent resistance to buckling and twisting, which is essential when a member is squeezed from both ends by the weight of a building.

Universal Column vs. Universal Beam: Key Differences

It is a common mistake to use the terms “beam” and “column” interchangeably. However, they serve two very different mechanical purposes:

| Feature | Universal Column (UC) | Universal Beam (UB) |

| Shape | Squarer (Depth $\approx$ Width) | Narrower (Depth > Width) |

| Primary Load | Vertical / Compression | Horizontal / Bending |

| Web & Flange | Thicker web and flanges | Thinner web and flanges |

| Best For | Supporting weight from above | Spanning gaps (floors/roofs) |

Key Takeaway: If the steel is standing upright to hold up a floor, it’s a Column. If it is lying flat to support a floor joist, it’s a Beam.

Common Applications in Construction

Universal columns are incredibly versatile and are used across various sectors:

-

Residential Construction: Supporting the weight of an upper floor during a “knock-through” or home extension.

-

High-Rise Buildings: Acting as the primary skeletal framework to transfer massive loads down to the foundation.

-

Industrial Warehouses: Providing support for heavy machinery, mezzanine floors, and overhead gantry cranes.

-

Infrastructure: Used in bridge pylons and large-scale transmission towers.

Standard Sizes and Material Grades

Universal columns are specified by their nominal size and weight per meter. For example, a common specification might look like:

$203 \times 203 \times 46$ UC

-

203 x 203: The approximate depth and width in millimeters.

-

46: The mass of the steel in kilograms per meter (15$kg/m$).

Steel Grades

In the UK and Europe, UCs are typically manufactured in grades S275 or S355. The “S” stands for structural steel, and the number represents the yield strength. S355 is the modern standard for professional projects due to its higher strength-to-weight ratio.

Advantages of Using Universal Columns

-

High Compression Strength: Their thick flanges allow them to carry heavy vertical loads without bending.

-

Stability: The square cross-section offers high lateral stability, making them less likely to buckle under pressure.

-

Ease of Connection: Because the flanges are wide and flat, it is easy to bolt or weld horizontal beams and braces to them.

-

Sustainability: Structural steel is 100% recyclable, making universal columns an eco-friendly choice for long-term construction.

Summary

The universal column is an indispensable tool in a structural engineer’s arsenal. By providing a stable, high-strength vertical path for loads to reach the ground, these steel sections ensure that our buildings remain safe and durable for decades.

Post time: Dec-19-2025