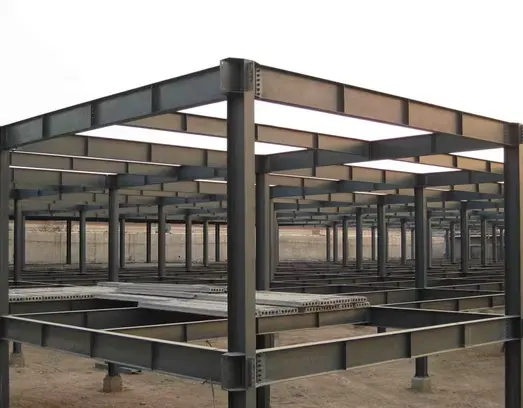

A fully boxed steel frame is a structural design in which steel members are enclosed on all sides, forming a closed rectangular or square section. Unlike open steel profiles such as I-beams or C-channels, a fully boxed steel frame creates a rigid, continuous structure that offers superior strength, stability, and resistance to twisting. This construction method is widely used in buildings, bridges, heavy equipment, vehicles, and industrial machinery, where high load capacity and durability are critical.

Understanding the Concept of a Fully Boxed Steel Frame

In a fully boxed steel frame, individual steel plates or sections are welded or fabricated together so that no side of the structural member is open. This closed configuration distributes loads evenly across the entire cross-section, reducing stress concentrations. The result is a frame that is stronger per unit of material compared to open-frame designs.

Fully boxed frames are often used in applications where torsional rigidity and resistance to bending are essential, such as long-span structures, heavy-duty platforms, and mobile equipment frames.

Key Features of a Fully Boxed Steel Frame

One of the defining features of a fully boxed steel frame is its exceptional structural rigidity. Because the frame is enclosed, it resists deformation under both vertical and horizontal loads. This makes it particularly effective in environments subject to wind, vibration, or dynamic forces.

Another important feature is improved torsional strength. Closed steel sections are far less likely to twist under uneven loads compared to open beams. This makes fully boxed frames ideal for applications where precision alignment and long-term stability are required.

Additionally, boxed steel frames offer enhanced durability. The enclosed design protects internal surfaces from direct exposure to impacts and environmental stress, especially when combined with protective coatings or galvanization.

Common Applications of Fully Boxed Steel Frames

Fully boxed steel frames are used across a wide range of industries. In construction, they are found in commercial buildings, industrial facilities, and steel structures that require high load-bearing capacity. In bridge construction, boxed steel girders provide excellent strength-to-weight ratios for long spans.

In the automotive and transportation sectors, fully boxed frames are commonly used in truck chassis, trailers, and heavy machinery. The design improves load handling and reduces frame flex, which enhances safety and performance.

Manufacturing equipment, conveyors, and material-handling systems also rely on fully boxed steel frames for their rigidity and long service life.

Advantages Over Open Steel Frames

Compared to open steel frames, fully boxed steel frames offer several advantages:

-

Greater resistance to bending and twisting

-

Improved load distribution

-

Increased structural stability

-

Better performance under dynamic loads

-

Longer service life with reduced fatigue

While open frames may be lighter or easier to fabricate, boxed frames provide superior performance in demanding applications.

Considerations and Limitations

Despite their advantages, fully boxed steel frames can be more expensive to manufacture due to increased material usage and welding requirements. Fabrication also requires precise workmanship to ensure proper alignment and weld quality.

Inspection and maintenance can be more challenging, as enclosed sections may hide internal corrosion if not properly protected. To address this, manufacturers often apply corrosion-resistant coatings or use sealed and treated steel.

Fully Boxed Steel Frames in Modern Design

Modern engineering and fabrication techniques have made fully boxed steel frames more efficient and cost-effective. Advanced welding methods, CNC fabrication, and high-strength steel alloys allow designers to maximize performance while controlling weight and cost.

Conclusion

A fully boxed steel frame is a robust and reliable structural solution designed for strength, rigidity, and durability. By enclosing steel members on all sides, this design offers superior load-bearing capacity and resistance to deformation compared to open-frame alternatives. While fabrication costs may be higher, the long-term performance and stability of a fully boxed steel frame make it an excellent choice for demanding structural and industrial applications.

Post time: Jan-23-2026