In structural engineering and construction, steel beams play a critical role in supporting loads and providing strength to buildings, bridges, and other structures. When reviewing blueprints, specifications, or steel catalogs, you might encounter designations such as W12x26 or W8x10. These are not arbitrary codes—each part of the label holds valuable information. But what exactly does the “W” mean in steel beams?

In this article, we’ll break down the meaning of the “W” in steel beam designations, explore how steel beams are classified, and explain why understanding this code is important for builders, engineers, and contractors alike.

What Is a “W” Beam?

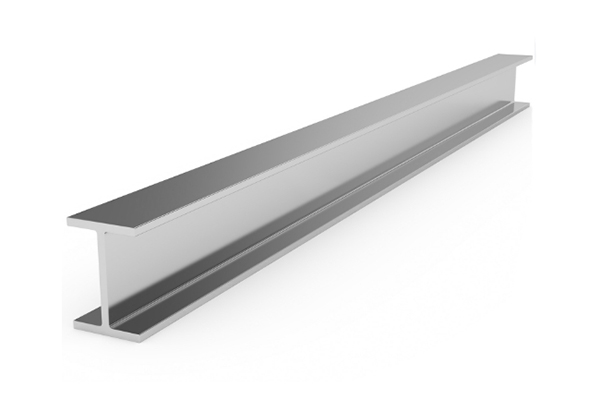

The “W” in steel beam nomenclature stands for “Wide Flange.” W-beams are the most commonly used type of structural steel beam in the United States and are known for their wide flanges and straight, uniform shape. The wide flange gives the beam a high strength-to-weight ratio, making it highly efficient for load-bearing applications.

In short:

“W” = Wide Flange Beam

Decoding a W-Beam Designation

A W-beam is typically identified using a two-part designation:

W x Nominal Depth (in inches) x Weight per foot (in pounds)

Example: W12x26

-

W = Wide flange

-

12 = Approximately 12 inches deep (nominal depth)

-

26 = 26 pounds per linear foot

So, a W12x26 beam is a wide flange beam that is approximately 12 inches deep and weighs 26 pounds for every foot of length.

It’s important to note that the “nominal depth” is not always the exact depth. For instance, a W12 beam might actually measure 12.22 inches deep, depending on the manufacturer’s dimensions.

Why Wide Flange Beams Are Popular

W-beams are preferred in structural design for several reasons:

-

High Load-Bearing Capacity

The wide flanges distribute weight efficiently and resist bending under heavy loads. -

Versatility

They are used in everything from residential buildings to high-rise towers, bridges, and industrial platforms. -

Standardization

Their dimensions and properties are standardized by organizations such as the American Institute of Steel Construction (AISC), making them easy to specify and use. -

Ease of Connection

The flat surfaces of the flanges make it easier to connect other structural elements using welding, bolting, or riveting.

Other Common Steel Beam Designations

While “W” is common in the U.S., other designations are used for different types of steel beams:

-

S-beams (Standard beams): Have a tapered flange and are designated with an “S”. Example: S8x23.

-

HP-shapes (Bearing piles): Designed for deep foundation work.

-

M-shapes (Miscellaneous): Shapes that don’t fit into standard W or S categories.

-

C-shapes (Channels): Often used for lighter loads or as secondary structural members.

Each designation provides insight into the geometry and strength of the beam and helps engineers select the appropriate type for specific applications.

Where You’ll See W-Beams in Use

-

Building frameworks for residential, commercial, and industrial construction

-

Bridge girders

-

Support columns

-

Large-scale platforms and mezzanines

-

Infrastructure projects like highways and rail systems

Conclusion

Understanding what the “W” means in steel beams is fundamental for anyone involved in construction, engineering, or architecture. It signifies a Wide Flange Beam, which is the most versatile and widely used structural steel shape in the industry. Recognizing the format of designations like W12x26 can help professionals make informed decisions about material selection, load calculations, and design safety.

By knowing what W-beams are and how to interpret their labels, you ensure that your structural projects are based on sound engineering principles and use materials appropriately rated for the job.

Post time: Jun-27-2025